In an earlier post about 3D printing, I joked about buying a phone online and then printing it right away. The difficulty, of course, is printing the electronics that go in the phone – the current hurdle is designing an ink that not only conducts electricity, but does so in a controlled manner. This week’s Economist has a nice run-down on the current state of the technology for doing exactly that.

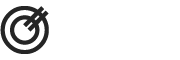

Xerox’s Silver Ink

Xerox has been developing a silver ink that can be used to print the actual circuits of the electronic device. Silver is a better conductor than copper but it’s expensive, so the ink uses a new process in which the silver is used in miniscule particles just 5 nanometers in size. This allows it to be relatively cheap and efficient.

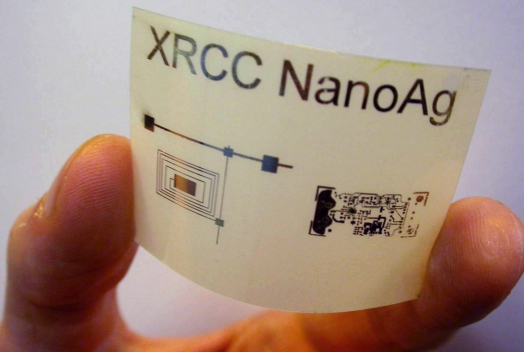

At Xerox PARC in Palo Alto, they have been experimenting with using this process to print flexible displays, sensors and antennae. Printing electronics with this kind of technology will allow much slimmer products than were previously possible. Watch out, MacBook Air!

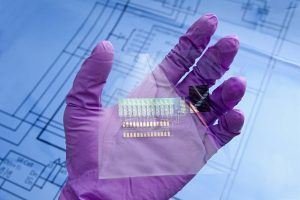

Optomec’s Aerosol Jet

Optomec, in Albuquerque, New Mexico has an alternate process they call Aerosol jet. Recently, in collaboration with Stratasys, a 3D printing powerhouse, they printed sensors, antennae and power circuitry directly onto the wing of a drone. In fact, the wing itself was 3D printed, allowing everything to be incorporated for an extremely lightweight, aerodynamic result.

You can read more about this at the Economist.

A new hurdle for this technology is printing the actual chips, since the density of transistors on a silicon chip is extremely high. Until we figure this one out, silicon chips will still have to be soldered onto the device. Nonetheless, the ability to print most of the other electronic components is a huge step towards a fully-printed electronic device.